ANTENNA

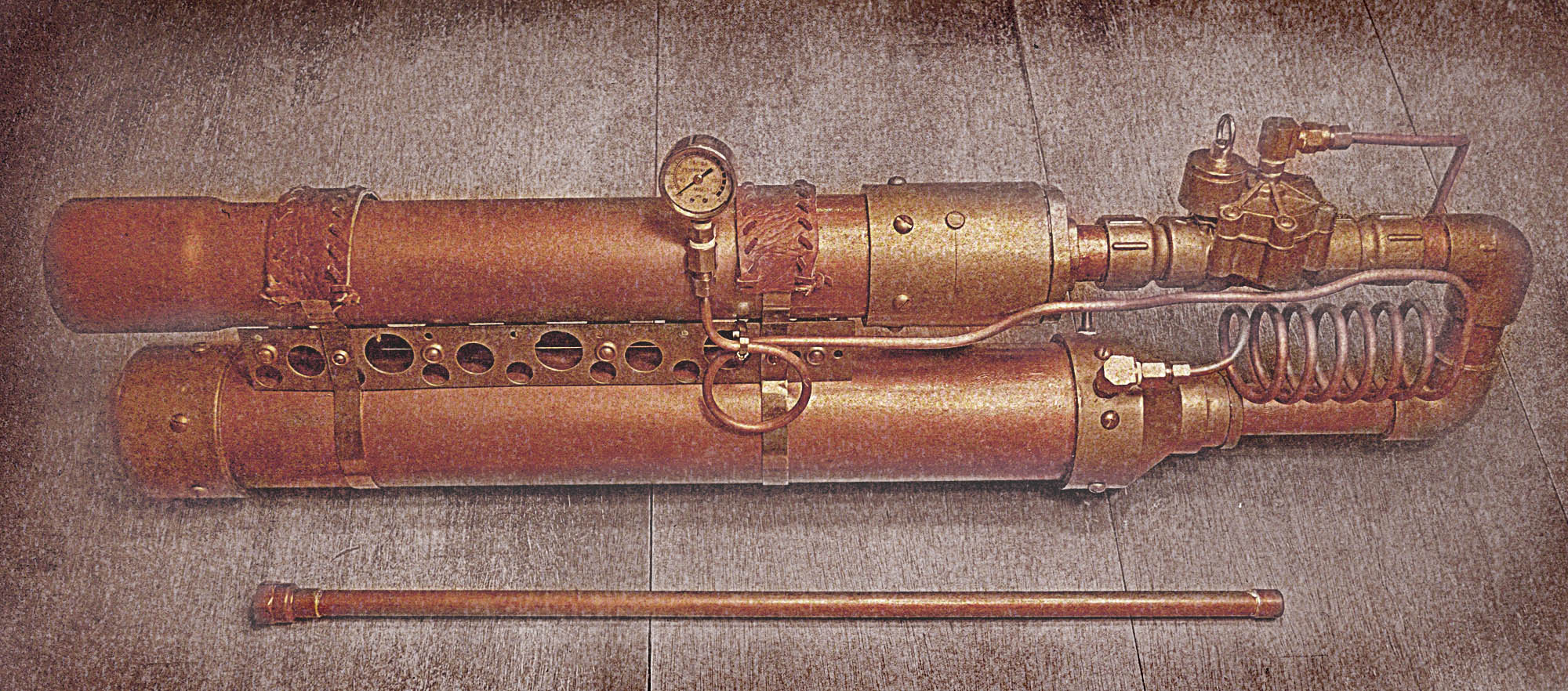

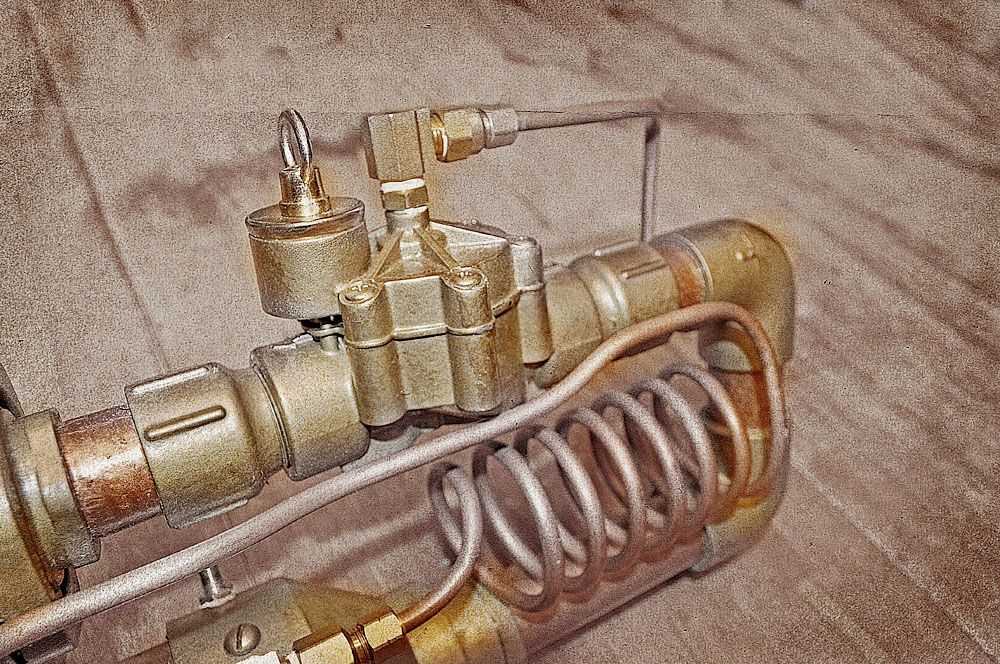

LAUNCHER "Steampunk" Styling -

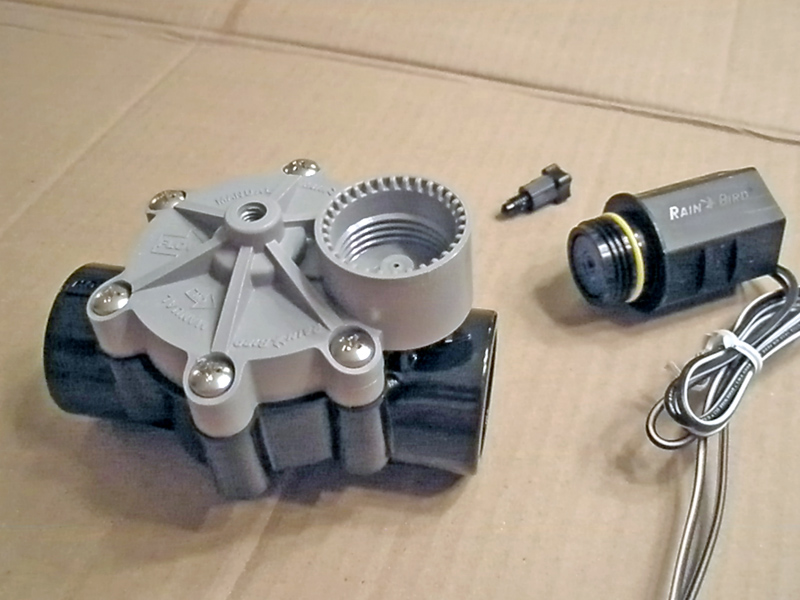

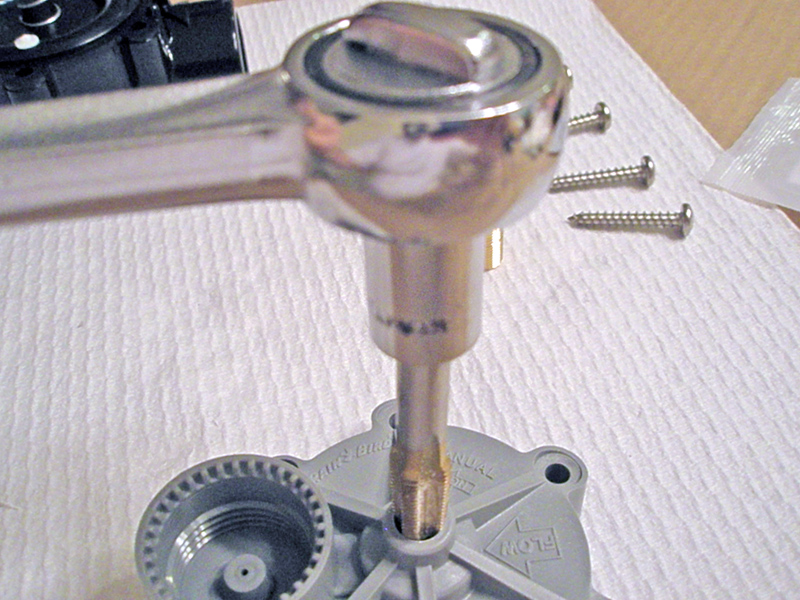

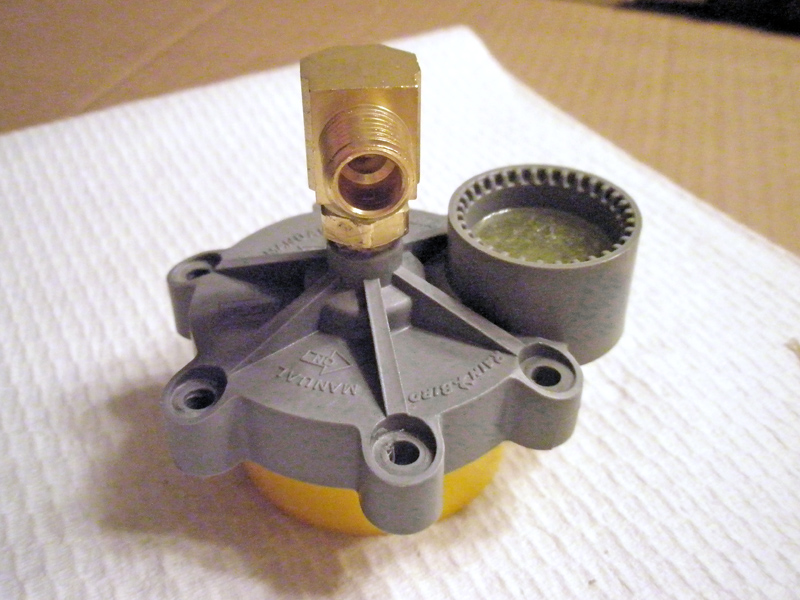

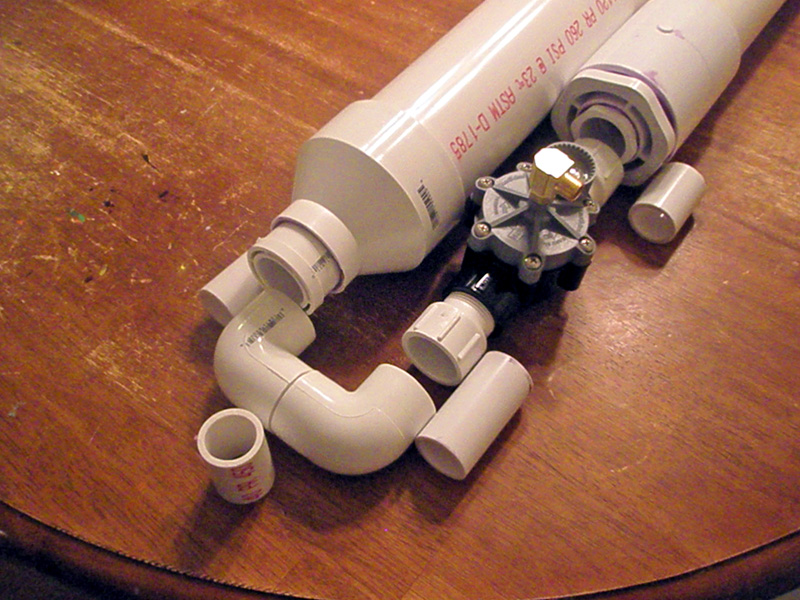

Sends tennis balls flying at 500 mph! This is the result of a week of creative spray painting. It has a copper and brass steam boiler look. The style is coined: "Steampunk". There is more aesthetic work planned for the launcher. After nearly throwing my arm out to install my three band dipole, and only getting it elevated around 45' up. I knew it was time to get a hold of a decent tennis ball launcher! These launchers use compressed air to accelerate a tennis ball to 300 mph pulling a tow line as high up as 150-400' in the air to allow for installation of ham radio wire antennas in the branches and tops of nearby trees.  We've used them at Field Day before and I was impressed with the results. The problem was where to find one... Could I simply make one? So I needed to do a little research. Well... it turns out that there is a great web site setup by a couple of hams just to satisfy the above qestions: http://www.antennalaunchers.com/antlaunching.html A great site that will educate you on the basics, intricacies and safety issues of procuring, building and using pneumatic antenna launching systems. SAFETY DISCLAIMER: Mike K4ICY and this site does not condone the use of this or related device if used within a legally forbiding jurisdiction or for inapropriate use that can and will threaten life, safety and property. You build one at your own risk and are encouraged to understand the many dangers associated with fabrication and use of any device that accelerates a projectile. All responsibilities and liability are that of the owner and builder. How does mine differ from the ones you can buy from Antenna Launchers.com? • POWER! My launcher has double the pneumatic charging volume and can launch the projectile to 300' with 80psi. • Less Cost... are you kidding?!?! Why pay $110 from someone, just to have to build it yourself? • Coolness Factor... (pictures soon) Mine has been decorated to have what's called a "Steam Punk" look. Styled after plausible technology of the late 1800's. Oh yeah! Everyone thinks it's made from real metal. What better PR device than a killer work of art at Field Day that is also functional! I am NOT currently buidling any, but will cave to making one at least once a year. If you choose to build one yourself, please make good notes from many of the website that teach the building of "Spud Guns" or "Tennisball Launchers" There are companies that sell parts such as barrels and valves. I will not get into exact dimentions and details. If you are able to build one, then you are apt to figure out the nuts and bolts yourself. There are two hurdles to overcome in procuring parts: The valve modification and obtaining the barrel material. The barrel must one, be the exact size as the diameter of a tennis ball (which varies) and be pressure rated. The best PVC pipe that I've found is called "SDR-21" and has an internal diameter of 2.6" I was fortunate to locate a supply at the local EWING Irrigation supply house. You can also go to a local plumber or plumbing supply house. NOT The Home Depot or Lowe's! But you will be able to readily find all the other required parts at those stores. The modification of the valve is easier than you may expect. These are simple devices sold by RainBird, Orbit and others and work on simple principles. All you would do is provide a quick escape of diaphram backside air pressure through a common air release mechanism to allow it to do it's thing. PHASE 1 Modifying the Sprinler System Valve Check out this YouTube video where there are step-by-step instruction on how to do this for your launcher or spud gun. http://www.wonderhowto.com/how-to/video/how-to-modify-a-sprinkler-valve-for-use-in-a-spud-gun-212056/  Parts needed for valve modification.

Available at your big-box home improvement store. Parts needed for valve modification.

Available at your big-box home improvement store.PLEASE NOTE: RainBird no longer manufactures this model type of valve and have moved to cheaper Mexican production. I am currious to see how the new type could me modded. But I'm sure you can do this to about every brand. Not all valves work exactly the same. But you should try to only work with the diaphram model and not the plunger version.  This is a common 1" sprinkle system valve found

at most hardware stores. You can get the connections in glue-in or

threaded. This is a common 1" sprinkle system valve found

at most hardware stores. You can get the connections in glue-in or

threaded.These type are intended for residential use and have a 24 volt controlled solenoid for actuatiion. There is also a pressure release control stem in the middle. Bigger and better ones can be used, especially if ridiculous amounts of "firepower" are needed. I do not recommend using the smaller 3/4" version.  Take those two items off, unscrew

counter-clockwise, and discard them. Take those two items off, unscrew

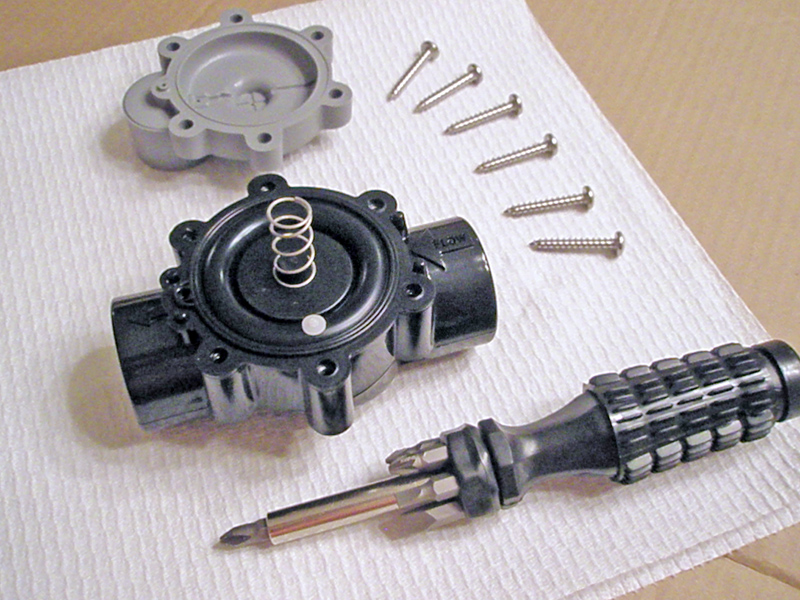

counter-clockwise, and discard them. There are six long screws. With some

downward pressure to budge the screws, remove them and carefully remove

the cover. There are six long screws. With some

downward pressure to budge the screws, remove them and carefully remove

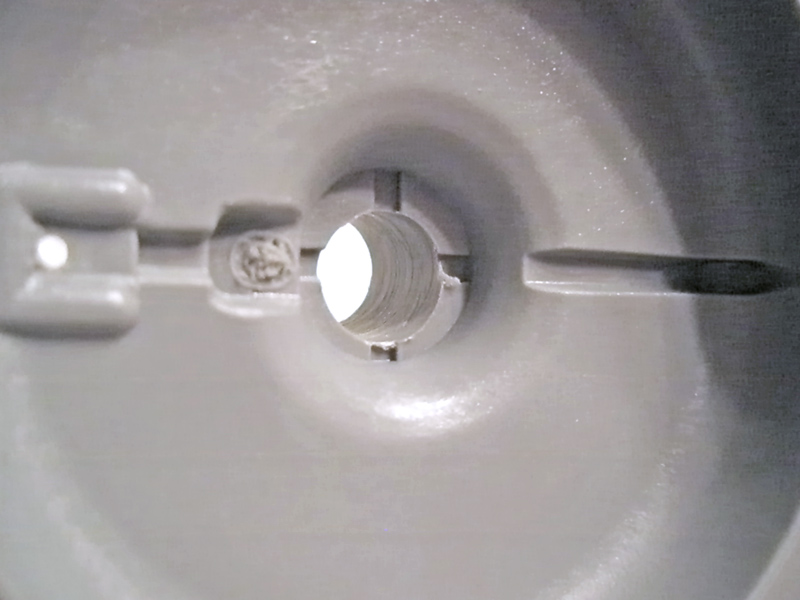

the cover.PLEASE NOTE the contents and location of the inside parts. Some valves have many. Generally just the spring, note its placement and the placement of the rubble diaphram.  This is the inside of the valve cover.

Note the THREE small breathing holes: This is the inside of the valve cover.

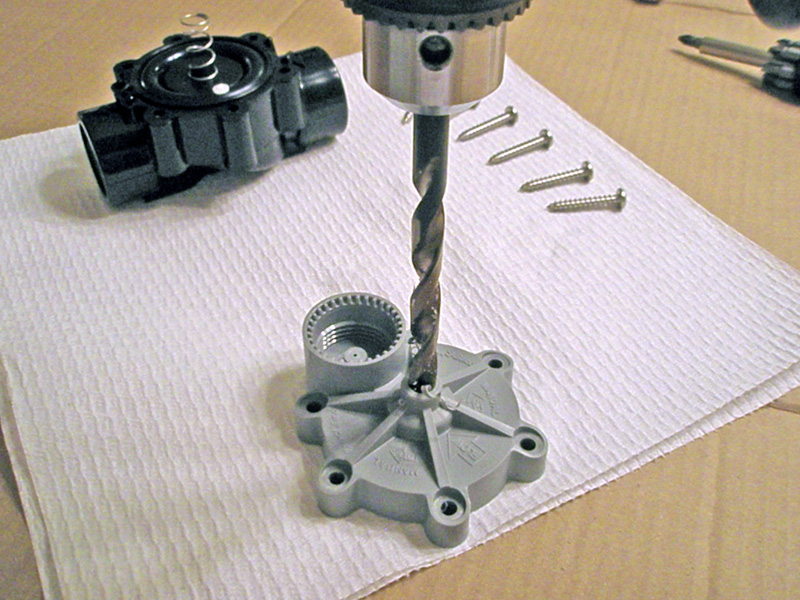

Note the THREE small breathing holes:The one to the left is for the air-from-solenoid intake port. The adjacent hole on the side of the dome is the air-to-solenoid port. The middle is the manual air-release control port. These holes are too small of adequate release of diaphram equaliztion pressure.  Use a drill to widen the center hole.

Start with a smaller diameter so that the stress on the plastic will be

reduced. Use a drill to widen the center hole.

Start with a smaller diameter so that the stress on the plastic will be

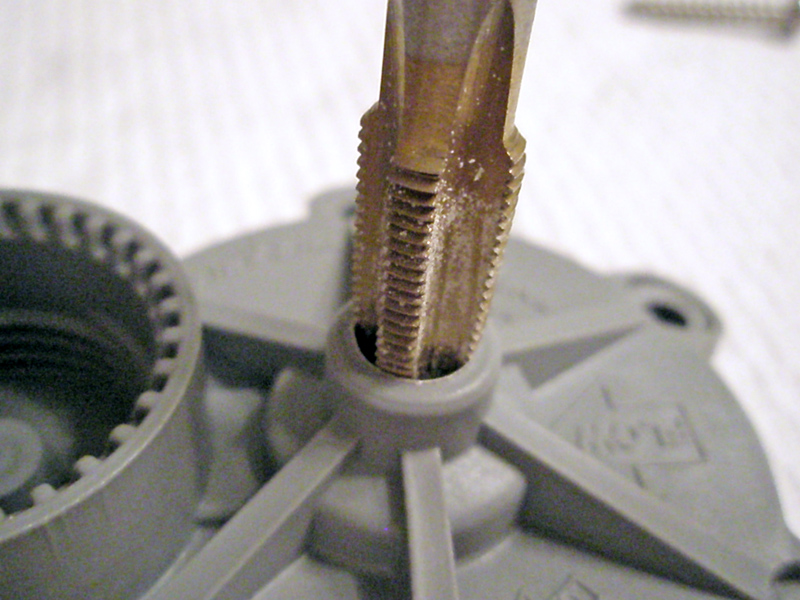

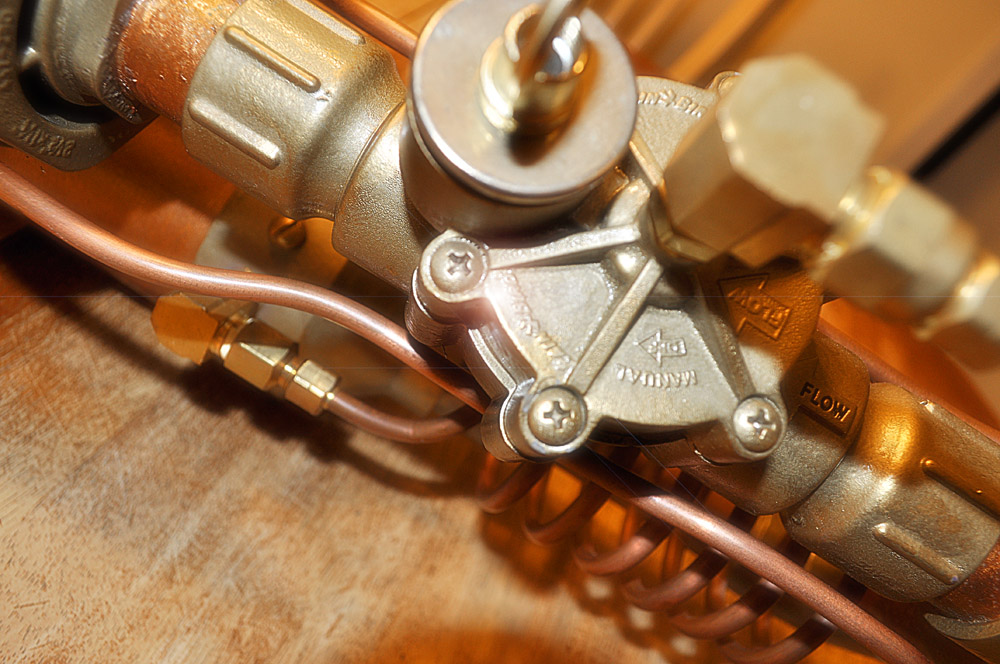

reduced.With this model, the center area is perfect with a good thickness to support the reducer connection.  Use a 1/8" NPT pipe thread tap. With level

and firm pressure, rotation of the tap should be done with a tap handle,

but a socket wrench works fine. Use a 1/8" NPT pipe thread tap. With level

and firm pressure, rotation of the tap should be done with a tap handle,

but a socket wrench works fine.Ocasionally remove the tap to remove excess shavings. Stop until 3/4th of the tap area is submerged. Tap lower if the treads are two narrow for the brass fitting.  Ensure that the tap area is at least 1/4"

in depth. Many valves lack the thickness in their cases to hold the

fittings. Ensure that the tap area is at least 1/4"

in depth. Many valves lack the thickness in their cases to hold the

fittings.The fittings will be holding the weight and user forces of the air-gun / trigger mechanism. And extra depth of high-strength polycarbonate epoxied to the surface my be required.   1/4" tapped hole in the valve

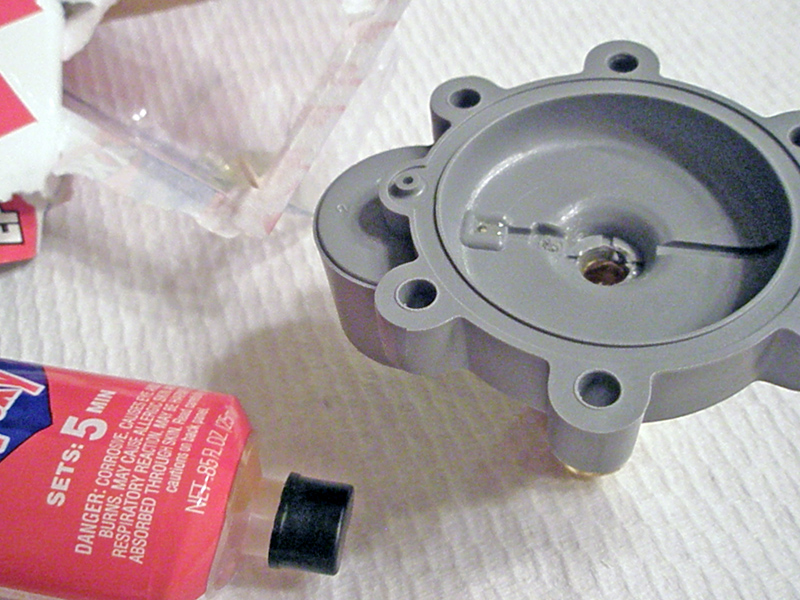

cover. 1/4" tapped hole in the valve

cover.Clean away any burs.  (Not shown) Brass NPT fittings are

combined with yellow (gas) teflon tape. I used a 1/8th" double ended

coupler and 1/8th-14th" elbow. (Not shown) Brass NPT fittings are

combined with yellow (gas) teflon tape. I used a 1/8th" double ended

coupler and 1/8th-14th" elbow.Mix the two-part epoxy, A very small quantity should do. Use a toothpick to spread it on the threads of both the cover hole and the brass fitting.  Apply epoxy with a toothpick to the

remaining breather holes. They are not needed. Apply epoxy with a toothpick to the

remaining breather holes. They are not needed.Carefully fill from both sides and avoid excess.  Go ahead and mix a small plastic cup with

more epoxy... hey! Why waste money. ...Plus, it's kinda weired

looking. Go ahead and mix a small plastic cup with

more epoxy... hey! Why waste money. ...Plus, it's kinda weired

looking.This will ensure that there will be no escape of air after future handling of the launcher and any possible unsticking of the epoxy... A mis-fire could be fatal!   (Top with air tap connection and epoxy

chamber fill.) (Top with air tap connection and epoxy

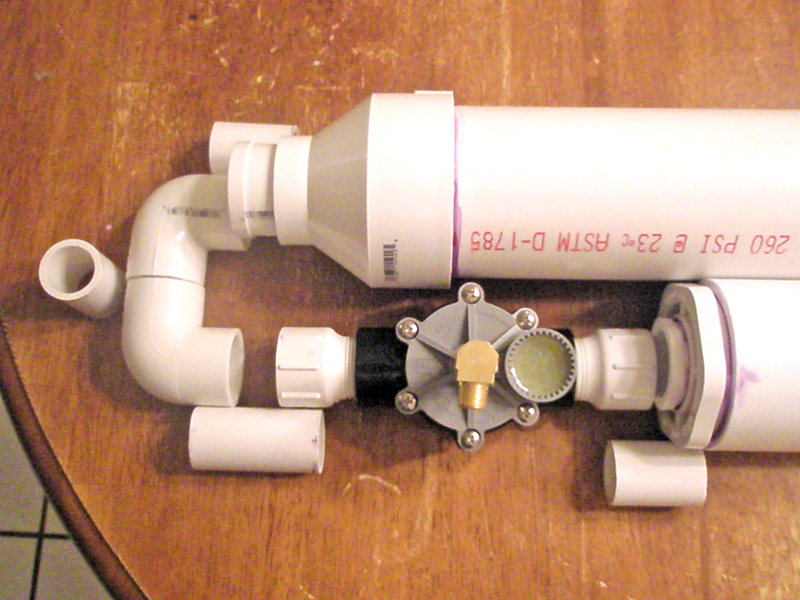

chamber fill.)Allow to set for 24 hours... Re-assemble, alternating screws (light at first) diagonally across valve cover. Then snug ensuring that the diaphram is not unevenly pinched. Ensure that there is no debris or dust inside the top of the diaphram chamber. Final vintage faux copper & brass look applied:   See below for procedure on painting PVC... PHASE 2 Assembling Lengths of PVC Pipe    Measure and cut all length of the diffrent sections from only PRESSURE RATED PVC. The overall look and performance of the tennis ball launcher is up to you. You can form any combination of shapes and power level that your wallet will allow. As long as the air has a pressure tank to be stored in, an inlet valve, firing valve and barrel.  Cap ends and reducer adapter links are

used to create the barrel and pressure tank. Cap ends and reducer adapter links are

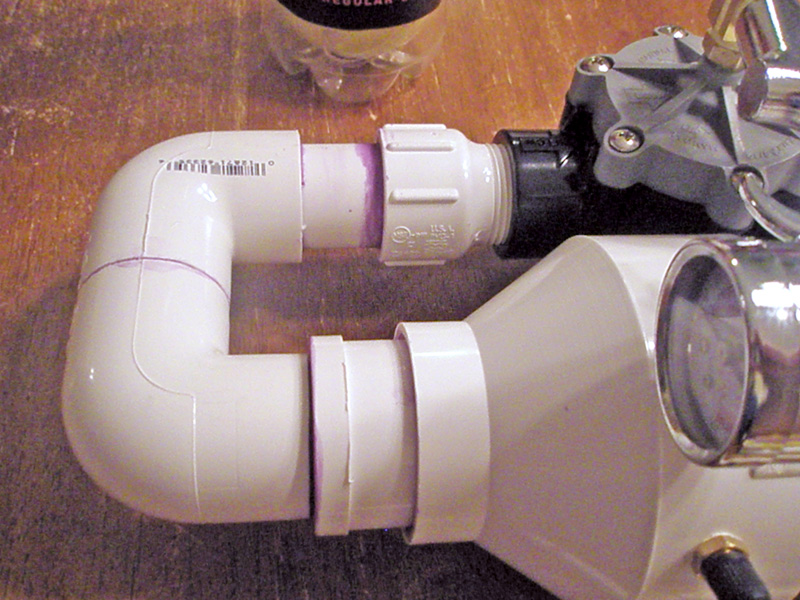

used to create the barrel and pressure tank.RULE OF THUMB: The pressure tank should hold at least twice the volume as the barrel. Volume = Pi x Inside Radius squared x length or pipe Though the barrel can be longer, and you may see greater velocity. If the tank is smaller, you'll have less acceleration of the projectile in the barrel.  (Adapter detail...) (Adapter detail...) (More detail) USE ONLY "MEK" High

Strength PVC primer. Avoid using the time friendly cement, as a strong,

air-tight bond is required. (More detail) USE ONLY "MEK" High

Strength PVC primer. Avoid using the time friendly cement, as a strong,

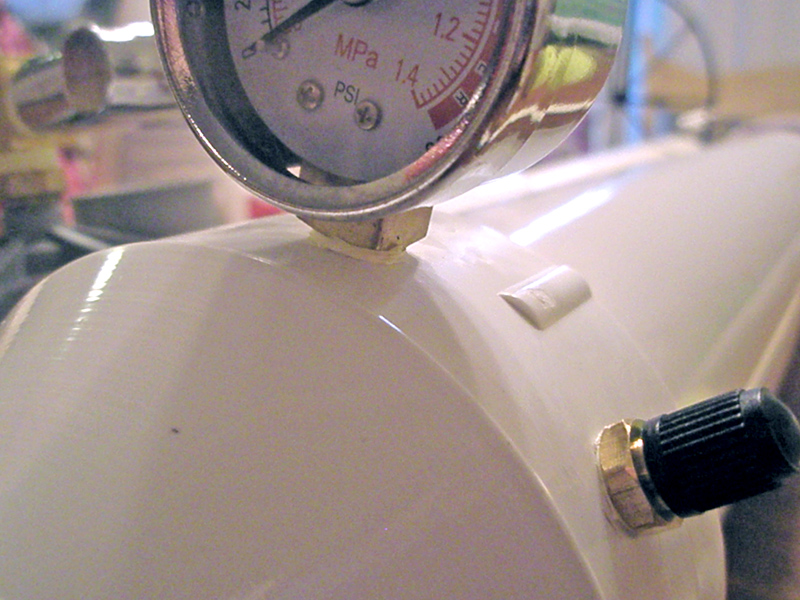

air-tight bond is required. BEFORE GLUING finished pressure chamber to

the rest of the launcher, BEFORE GLUING finished pressure chamber to

the rest of the launcher,drill, Tap and install the Schlader valve and optional over-pressure protection valve and optional pressure gauge first with yellow teflon tape. Blow out any shavings or dust that can contaminate the surface of the valves diaphram.  The barrel and pressure tank should be

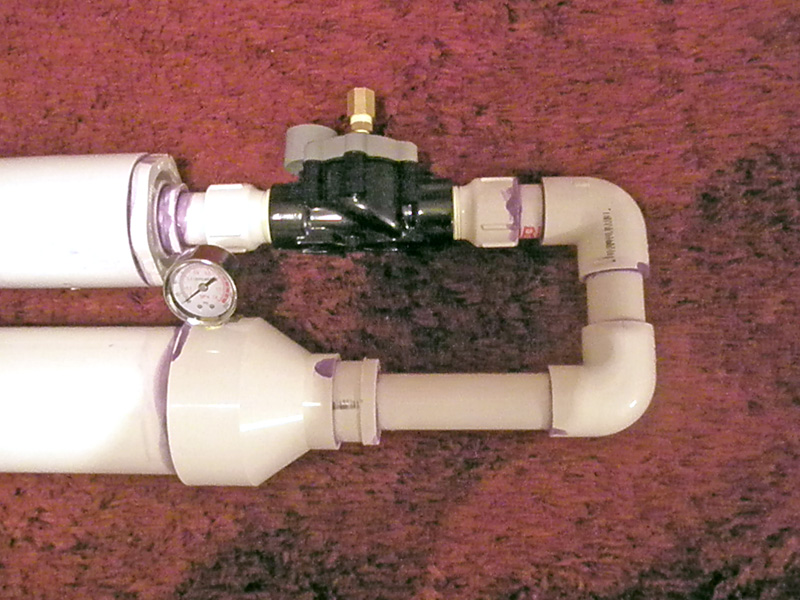

created first them arranged in your chosen configuration. The barrel and pressure tank should be

created first them arranged in your chosen configuration.PLEASE NOTE: If the valve is the threaded type, ensure that there is enough clearance to remove the valve if service is needed. PHASE 3 Finalization  Since the barrel and tank were only

connect by the 1" PVC length on the other end, it was important to shore

them up to prevent damage from shifting weight. Since the barrel and tank were only

connect by the 1" PVC length on the other end, it was important to shore

them up to prevent damage from shifting weight.I used a stainless-steel vent pipe strap for this model. The first model has an intricate stucture of brass and steel that is more for show.  Attach the valve trigger, I used a common

pneumatic air gun. Attach the valve trigger, I used a common

pneumatic air gun.You can route to another location by use of an air hose or a fast release solonoid valve... whatever you wish. The faster the release of air on the control side of the diaphram the more launch performance you will get.  This is a tennis ball projectile. You may

use other projectiles such as a slug made from PVC links, golf balls,

potatoes, squirrels (don't!), etc... This is a tennis ball projectile. You may

use other projectiles such as a slug made from PVC links, golf balls,

potatoes, squirrels (don't!), etc...The tennis ball is widely used by the ham community because of it's safety when falling, where-as the traditional methods, namely lead sinkers, arrows and wrenches are dangerous! Making the ball is simple: Cut a 1.5" gash in it with a knife. Fill with a baggie of 30 pennies for good weight (which increases velocity!). Make a few loops of 30-40 lb test weight mono-filiment fishing line and seal the loops halfway into the gash with a adequate application of Super Glue. I prefere the Gorilla brand rubberized Super Glue. Cure overnight...   Here is the final assembly. Two slight

variations are shown. Here is the final assembly. Two slight

variations are shown.Certain brands of tennis balls are a tight fit but provide improved velocity. A chuck should be made. PHASE 4 Testing It is very important to test your launcher before field use!!! • Fill air chamber with 20 psi to begin testing for catastopic failure. Submerge the launcher in the bath tub or place under a few towels as shrapnel from exploding PVC can be leathal! • Take out of water and squease the valve trigger... It should make a "barking" barking noise. I suggest using ear-plugs as the release of pressure and noise decibel level can be harmful. • Increase pressure by 20 psi until you reach the maximum. - PLEASE NOTE: You should be safe if you never excede 1/3 of the max psi rating on the largest (thus weakest) PVC pipe. Since I'm using 3" pipe for the tank, and it's rated at 260 psi, I use 90 psi as my max... It does well. I can send a ball 400" (at a 45 degree angle), so it should be sufficient for ham use. • Take to an open field and try the projectile by itself. Start off at smaller psi incerements and gauge the height and distance that each level brings. You'll notice that it is expontial. DESIGN NOTES: • When a thicker diameter ball is used and when more weight is added the resultant back pressure will cause the projective to go farther and faster. • Be carefull to tighten connections and seals. Loss in air pressure in the trigger line will cause uninteded misfirings!!! • 40 or 50 lb test fishing line with an easy sun-catching day-glow color is recommended for the tow line. SAFETY RULES AND PROCEDURES: 1) LEAVE BARREL CHAMBER EMPTY 2) ONLY FILL TO SAFE PRESSURE LEVELS - DO NOT OVERFILL! 3) POINT AWAY FROM PEOPLE, PARTS OF YOUR BODY, PROPERTY, PETS, ETC. 4) NEVER - NEVER - NEVER AIM OR FIRE THE LAUNCHER WHERE THE PROJECTILE OR TOW LINE CAN COME IN CONTACT WITH ELECTRICAL SERVICES 5) FIRST POINT LAUNCHER STRAIGHT UP IN THE AIR, PLACE BALL IN AFTER. THEN AIM SLIGHTLY HIGHER THAN TARGET TO ADJUST FOR DRAG. 6) WARN NEARBY PEOPLE 7) DEPRESS TRIGGER QUICKLY AND HOLD  Launcher in action at the Jamboree On The

Air. Launcher in action at the Jamboree On The

Air.HOW TO PAINT PVC PLASTIC: 1) First - Clean surface with alcohol and lightly sand with a high grit to rough up the surface. 2) Coat entire surface with a liberal application of "Purple Primer"  This is an agressive solution of Tetrahydrofuran and

Methyl Ethyl Keytone. Very toxic to breath, but effective. This is an agressive solution of Tetrahydrofuran and

Methyl Ethyl Keytone. Very toxic to breath, but effective.3) Within the first few minutes after the excess liquid primer has evaporated - Paint surface with a nuetral color Spray Paint formulated for PVC plastic. The spray paint manufacturers claim that this paint will adhere to PVC. But in real life, it usually peels off after a while. 4) Apply a new coat, once dry to the touch, with the spray paint color of your choice. - Re-apply with second or third coat later. For a vintage finish there are paints for that. Metal can be achieved by first applying a standard metallic color. These usually have a flatter look. Then patting on a super reflective chrome-like version of the paint with a paper towel or sponge. Other effects, like corrosion or weathering, can be done with diluted mixes of other paint colors. |